We are often asked why we have 3 products for treating wood. Are all 3 necessary and if so, how should they be used together? Can I skip Wood Boost?

The answer is that each has an important but different role to fulfill to give wood the very best possible protection. Wood Fresh is an essential first step for restoring the natural colour and texture of grey or faded/weather-bleached surfaces – without the usual rubbing down with glasspaper or sandpaper. It is a highly effective, labour-saving cleaner and refresher for all kinds of timber. It is particularly recommended for use on laminated wooden surfaces where abrasive treatment might remove or significantly damage the top layer. Blue and black fungus, bacteria and weathered and loose wood/cellulose fibres are effectively removed without effort. Amazingly, without any sandpapering or grinding, wood regains its original colour and structure.

Wood Boost is the next step. Yes, you could miss it out but by using it you will protect the wood surfaces against the adverse effects of the weather, reducing bleaching and greying and extending the life of the wood by up to 4 times longer than if left untreated. The reason is that unlike a paint or varnish, Wood Boost penetrates deep within the wood, strengthening the structure and preventing the ingress of moisture, actually eliminating signs of “wear and tear”. It can also be mixed with wood dyes to achieve the desired finished colour.

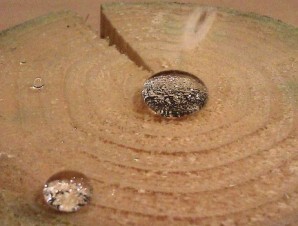

The finishing touch is Wood Prodeck which protects woods – especially hardwoods – against water saturation, swelling and rotting. Its breathing and practically invisible coating allows water and oils to simply “pearl-off” taking dust and dirt away. Dirt and stains simply cannot penetrate the wood and therefore there is no marking or flecking. Even in extreme cases of exposure to rain or condensation, the wood absorbs absolutely no moisture – it just remains on the surface where it can be easily wiped off or just allowed to evaporate. This means that drying time is drastically reduced and with no moisture in the pores of the wood, damage from frost prevented. The product is ideal for all types of wood including untreated, absorbent and even pressure- impregnated structural timber. It is able to be used both for indoor and outdoor purposes.

HOW TO APPLY WOOD FRESH

Do not dilute. The surface to be treated must be dry, free of any other coating materials, free of dirt/dust and also any paint remains/particles. If applicable prepare the surface first. Should there be painted surfaces adjacent to the area to be treated, make an experimental test in a place which is not immediately visible. The product should be used at a temperature above 10 °C. Any plants should be first covered for protection, or generously sprinkled with water to prevent any accidental oxidation.

Apply completely covering with a brush and work thoroughly into the wood. On vertical surfaces work from the bottom to the top. Let the coating start working for a period between 1 and 2 hours. Do not let dry out. Apply again if it is going to be dry. Spray the coated area using a pressure jet at an angle of 45 degrees to the treated surface using lots of water. Do not use too much pressure, to prevent damage to the wood fibres. Alternatively use a strong water jet., applying with upward strokes starting from the bottom working upwards, and rinse thoroughly. The quality of the result is more dependent upon the amount of water, rather than the pressure used.

For very heavily soiled surfaces a second treatment may be necessary. The renovation is completed when completely dried. It is essential to wear plastic gloves and protective glasses/goggles together with an overall suit when working with this product because Nanolia Wood Fresh oxidises on the skin or soft membranes.

HOW TO APPLY WOOD BOOST – when the wood is almost completely dry!

Do not dilute. Shake well. The two parts should be mixed completely. The moisture contents of the wood should not exceed 18%. Apply the product with a brush in a thin coating in two layers. After a drying period (dependent upon the moisture of the atmosphere and the absorption of the wood – a period of about 4 to 6 hours), the second coating may be applied. The longer the drying period, the more effective the protection. The intensity of the wood structure and the colour depend upon the method of application and it is therefore recommended to make a trial application.

Make sure that the surface is completely dried when applying Nanolia Wood Prodeck afterwards. It may take several days to have a completely dry surface.

HOW TO APPLY PRODECK

Shake the product well. Use undiluted. The surface to be coated must be dry (wood moisture max. 18%) clean and free of fat/oil. Use a roller or brush to apply very thinly, but covering the entire surface. On absorbent surfaces a second coating is recommended “wet-on-wet”. The more the product enters the wood, the more the preservation lifetime is extended. Superfluous coating product can be removed by wiping with a damp cloth in order to prevent any stickiness. Please avoid putting used material back to the original package. Any materials close to, or adjacent to the surface to be treated do not need to be masked (i.e. glass or rubber seals). When applied to light coloured woods the result is a slight honey-colour.

When Nanolia Wood Prodeck AB is used there will be a slight darkening of the surface. It is possible that some flecking/marking will appear if there are any traces of oil in the treated wood. Previously treated surfaces may be affected in different ways from the weather, and therefore may have various degrees of porosity. As a result there may be a minimal amount of “shadowing”. It is highly recommended to make a “trial-surface” on the surface type to be treated. The drying time is approx. 2 hours. To maintain the “pearling-off” effect a new coating should be applied yearly. The impregnation is active even if the “pearling-off” effect on the surface is reduced. After weather exposure all products may be overcoated with solvent-based paints.