- Permanent "easy-to clean" finish

- Graffiti attacks can be removed without damaging the protective layer

- UV radiation shield prevents the underlying colour from fading

- Excellent durability

- Abrasion resistant

- Resistant against acid and alkaline attacks and organic solvents

- Extremely high coverage due to very thin coating

- Permanent “easy-to-clean“ finish

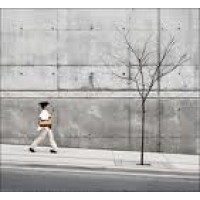

GRAFFITI GUARD FOR POROUS SURFACES™

Graffiti Guard for Porous Surfaces is a permanent, high-performance water-based protection for absorbent mineral surfaces such as concrete, masonry and natural stone. Free from organic solvents, it creates an invisible hydrophobic, oleophobic, breathable and weather-stable surface that also impedes the growth of algae, lichens and mosses.

The perfect defence against graffiti, Graffiti Guard for Porous Surfaces is resistant to attacks from solvents, acids and alkalis. Paints and coatings simply cannot penetrate the surface and so can be readily removed without the need for harsh abrasive scrubbing. Treated surfaces can be easily cleaned with Nanolia AG GRAFFITI REMOVAL LIQUID or AG GRAFFITI REMOVAL GEL up to 6-8 times without having to renew the protective layer.

Nanolia’s Graffiti Guard for Porous Surfaces meets all relevant requirements of the German Quality Association Gtegemeinschaft Anti-Graffiti e.V. It is suitable for all mineral surfaces such as concrete, masonry and natural stone. It is not, however, suitable for marble, granite or non-mineral plaster and painted surfaces for which we have other products such as Stone Guard, Concrete Protect, Stone Coat, PowerCoat, PowerCoat Pro and Graffiti Guard for Non-porous Surfaces.

| Technical Data: | |

| Mixing proportions | Ready to use |

| Dilution | Can dilute 2.5% for spray applications |

| Finish | Impregnation |

| Colour | Transparent |

| Layer thickness: | N/A |

| Temperature range | 5° – 40°C |

| Pot life | approx. 6 hours (at 20° C) |

| Dust drying time* | approx. 6 hours (at 20° C) |

| Completely cured*: | approx. 2 weeks (at 20° C) |

| HVLP Spray | Nozzle: 0.8 mm; Pressure: 2.0 bar, roll or paint |

| Spread rate on dry wall: | approx. 8m ² – 12m ²/kg |

| *Application at ambient temperatures below 5°C will affect the outcome | |